In response to the challenges of assembly methods for existing sandwich panels, the team at Harper Engineering Co. has introduced its own panel fastening system. Our panel fastening system includes a family of unique inserts that could be custom made to fit any panel thickness, curvature, and mating angle resulting in limitless panel joint configurations. In addition to limitless configurations, we are proud to bring the efficiency of the furniture-in-a-box industry to aerospace. This approach eliminates the need for fixtures or adhesives during assembly, allowing to pre-finish panel components and ship them in a flat-pack format. Allowing for a decreased rework cost associated with separating bonded panel assemblies.

Learn more

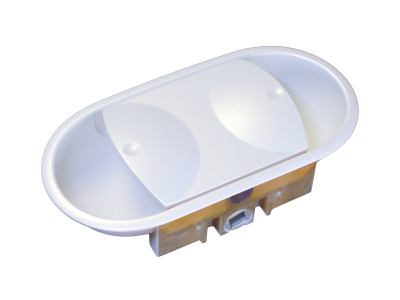

Team at Harper Engineering Co. originally has developed molded-in locking inserts (also known as low-profile molded-in locking blind inserts) to be used exclusively for our own panel fastening system. Although, later it was offered for customers as a solution specifically designed for situations where the amount of space is limited, particularly in plastic materials.

Learn more

We offer a variety of decorative washer products which are available in a wide range of sizes and finishes including aluminium and stainless steel.

Learn more

Harper Engineering Co. initially collaborated on the development of seat track fittings specifically designed for Boeing 787 Dreamliner. These fittings were designed with inconel fasteners and a forged titanium body to enhance the installation process of Original Equipment Manufacturer (OEM) seats. Since then, we have further enhanced our initial design, surpassing the capabilities of other fittings on the market both in terms of strength and weight reduction. The improved design now offers a capability exceeding 14,000 pounds and can be configured either as a bolt-down or a snap-in fitting.

Learn more

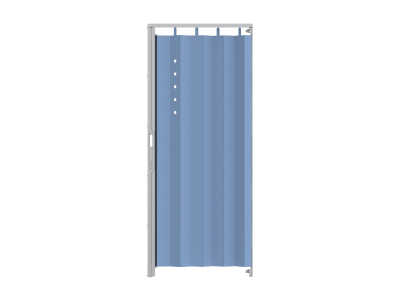

Since the introduction of Saracini Aviation Safety Act in 2018 our team of engineers worked hard to design and prototype the solution of the secondary barrier to the cockpit that would increate the safety of everyone onboard.

Learn more

Harper Engineering Co. manufactures lightweight, high performance, and press-formed CFRTP (Continuous Fiber Reinforced Thermoplastic) stowage bin covers for 787, 747-8, and 777X aircraft from our composites manufacturing and injection molding facility in Kent, Washington.

Learn more

With over 50 years of experience, Harper Engineering Co. has been dedicated to designing and manufacturing unique and exceptional stowage bin latching systems. Each of our bin latching systems are customized to meet specific requirements of our customers, guaranteeing a perfect fit. We are committed to deliver unparalleled quality and reliability, ensuring that our latch systems are built to last.

Learn more

Harper Engineering Co. has a proven track record of delivering latching systems that seamlessly integrate with the ceiling panels of aircraft structures. Whether it's for high volume Original Equipment Manufacturer (OEM) projects or one-off VIP aircraft configurations, we excel at handling latching systems with challenging requirements (such as deflection, anti-rattle, decompression, and limited access).

Learn more

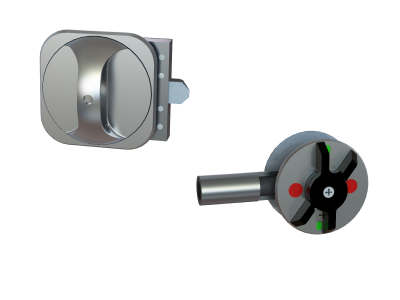

Harper Engineering provides an extensive range of door latching systems designed for various interior elements, including galleys, lavatories, crew rests, and other interior monuments. Additionally, we specialize in offering high-security products for applications such as flight deck doors that require ballistic protection. Our door latching systems are equipped with a range of unique features to meet diverse needs. These features include overridable key locks, combination locks, decompression release mechanisms, multi-point latching, seamless bezels, and many more. We aim to offer comprehensive products that prioritize both security and functionality, ensuring that our door latching systems meet the specific requirements of each application.

Learn more

Harper Engineering Co. consistently produces and ships thousands of bottle brackets to customers worldwide on a monthly basis. In addition to manufacturing standard-sized bracket systems, we have the capability to create brackets for non-standard sizes as well. This allows us to accommodate the unique requirements of our customers, ensuring that our bracket products fit their specific needs, regardless of size and shape.

Learn more

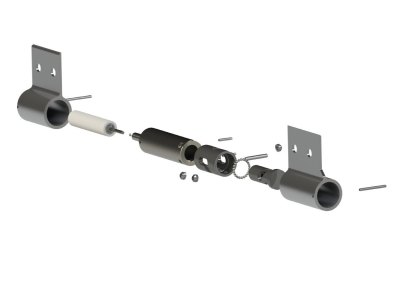

Harper Engineering Co. provides a range of hinge options, from basic spring-loaded piano-style hinges to a more intricate 6-bar mechanisms designed for doors with specific travel path requirements. Additionally, we offer unique applications such as dampened constant force shelf bin door hinges, which are integrated into the sidewall panel of the bin to maximize luggage capacity.

Learn more

Harper Engineering Co. offers a diverse range of products that cater to a wide variety of application, with combined sales quantities in the millions. We classify these versatile products as "Universal" due to their ability to serve multiple purposes across difference industries and sectors. Some examples of our "Universal" products include decorative washers, spring-loaded door snubbers, lock and key combinations, hat clips, etc.

Learn more

Harper Engineering Co. possesses the technical expertise and manufacturing capabilities to handle a wide range of products, from coat hooks to high-temperature silicone overmolded stainless steel gaskets, and everything in between. We are fully equipped to see any project through to completion, ensuring that the end result not only meets but surpasses expectations in terms of quality and performance. Our commitment to excellence ensures that we deliver products that are unrivaled in terms of their reliability and functionality.

Learn more